Lindt Difference –

What makes Lindt chocolate so exceptional?

-

Finest cocoa

The secret of Lindt’s unique taste lies in the careful selection and blending of premium cocoa beans from the world’s most exclusive regions of origin, coupled with highly skilled production methods.

beans from the most renowned REGIONs

Lindt & Sprüngli sources its premium cocoa beans from the world’s very best regions of origin, such as Ghana, Latin America (mainly Ecuador), the Caribbean, Madagascar, and Papua New Guinea. In our recipes, we use special blends of cocoa varieties from different regions. These bean combinations are a closely guarded secret and are what give our chocolates their exquisite taste.

responsible way of producing sustainable cocoa

Show moreLindt & Sprüngli is one of the few “bean-to-bar” chocolate makers in the world, with full control of the production chain, from the selection of cocoa beans to the end product. On the one hand, this approach allows us to control the entire manufacturing process and thus guarantee superlative product quality. On the other hand, this ensures our commitment to sustainability is maintained along the entire value creation chain.

The unique taste of Lindt chocolate is the result of careful selection, blending, and processing of premium cocoa beans from the world’s best regions. But it is not just high quality standards that play a key role: our sustainable supply chain is equally important. This was the rationale behind the launch of the Lindt & Sprüngli Farming Program in 2008. The Program pays a voluntary price premium for every ton of cocoa beans purchased, which is then invested in the traceability and verification of cocoa beans. Our Farming Program helps to boost farmers’ crop yields, thereby not only improving their livelihoods, but at the same time securing the long-term supply of premium cocoa beans for Lindt & Sprüngli.

LINDT & SPRÜNGLI?

FARMING PROGRAM56,000 Cocoa farmers trained in the Farming Program:The Lindt & Sprüngli Farming Program consists of four steps:

- Set-up of traceability

- Training and knowledge transfer

- Farmer investment and community development

- Verification and continuous progress

Product commitment

100% Traceable and verifiedIn 2016, Lindt & Sprüngli successfully achieved its aim of sustainable cocoa sourcing: the entire supply chain for cocoa beans from Ghana is traceable and verified. Additionally, first progress is also made in Ecuador and Madagascar.

-

UNIQUE ROASTING AND GRINDING PROCESS

Lindt Master Chocolatiers roast the cocoa beans using a process refined over decades and then grind them down to an extremely fine texture – essential for the unique taste of Lindt chocolate.

the art of creating the perfect aroma

The cocoa varieties are mixed together according to top-secret recipes and then the beans are split open. Next, the so-called cocoa nibs are roasted to bring out their special aroma. Here Lindt & Sprüngli uses a special method in which the roasting temperature and times are perfectly matched. After roasting, these cocoa nibs are reduced to cocoa mass in special grinders and then mixed with other ingredients before being crushed to minute particles on massive rolling mills. This is one of the reasons why Lindt chocolate really does melt in the mouth.

the essence – a smooth chocolate texture

Show moreLindt & Sprüngli processes the cocoa beans into cocoa mass in Switzerland, France, and the US. In Switzerland for example, our dedicated European Cocoa Center is in Olten. Here the carefully selected premium cocoa beans are weighed and mixed according to precise recipes.

The actual bean mix in each case is a closely guarded manufacturing secret, as the expert blending of the flavors of the individual bean varieties from different provenances is what gives the chocolate its special taste. After blending, the cocoa beans are placed in special machines for “winnowing”, where the husks are split open and removed by mechanical sifting and air currents, leaving behind the cocoa “nibs”. The nibs are then roasted using a specialized process, which is what gives the cocoa its unique and exquisite aroma. Lindt & Sprüngli deliberately roasts just the nibs rather than the entire cocoa beans, to achieve a very uniform roasting process. As with coffee, the cocoa beans may have a light or dark roast depending on their eventual use. It is a well-known fact that roasting certain foods not only makes them easier to digest, but also intensifies their aroma. This is why, for example, Lindt & Sprüngli also roasts all its hazelnuts and almonds in-house.

Very soon after that, they are processed into the end product so as to ensure that the chocolate retains the delicate flavor of the roasted beans. Roasting is one of Lindt & Sprüngli’s core skills and requires a very sophisticated process that ensures a perfect match between roasting temperature and duration. The cocoa nibs, which have been roasted but are still relatively coarse, are then cracked and ground very finely in special mills. The heat created by the pressure and friction liquefies the cocoa butter contained in the beans to produce a thick paste known as cocoa mass. The cocoa mass is dark brown in color and has a strong characteristic smell and flavor. It provides the basic material for the next stage of the chocolate-making process. The cocoa mass is then mixed with other ingredients such as cocoa butter, sugar, vanilla, and dried milk powder (depending on the recipe), and ground even more finely in our Kilchberg factory. At Lindt & Sprüngli, the chocolate mass is passed through the rolling mill twice to ensure it is reduced to the tiniest particle size possible. This stage of processing also requires specialist know-how and is an important component of the Lindt Difference, as the extremely fine particles in the cocoa mass are what gives Lindt chocolate its unique melt-in-the-mouth texture.

how cocoa beans are turned into cocoa liquor

-

The Lindt Invention

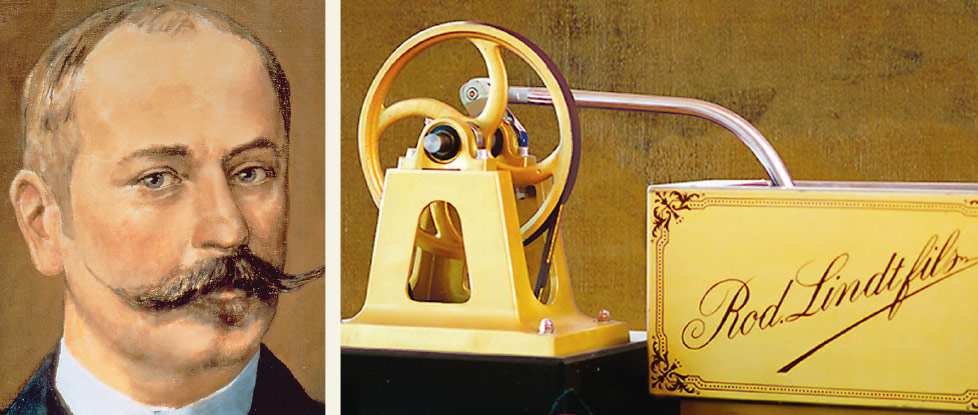

In 1879, Rodolphe Lindt revolutionized chocolate-making by inventing a technique known as “conching”: the chocolate mass is heated and beaten vigorously to produce the creamy, velvety texture of Lindt chocolate.

the secret of smooth melting chocolate

In 1879, Rodolphe Lindt invented conching, a revolutionizing process that alterated the entire chocolate industry. The technology has been continuously refined since then, and today the ground-breaking invention of our pioneer founder is now used throughout the industry. Vigorous beating heats up the chocolate mass in the “conche” and cocoa butter is reduced to the finest particle size. This produces the velvety melting texture that makes Lindt chocolate so special.

Tradition and Innovation of the Conching Process

Back in 1879, Rodolphe Lindt, the son of a pharmacist in Bern, wanted to make chocolate. In those days, chocolate was very different. For a start, it was hard: hard to process and hard to eat. In fact, you had to chew it. Melt in the mouth? A real treat? A joy to the senses? Unfortunately not! Lindt only realized his dream one evening when … But wait! Things did not move quite so fast. Initially Rodolphe Lindt, confectioner, epicurean, and bon vivant, simply wanted to create a type of chocolate that was not hard.

Show moreSo he bought an old factory with ancient machines. Bernese society wondered what he was up to, but Rodolphe would not be discouraged. Although he experimented, nothing seemed to work. On the contrary, a thin white film formed on the chocolate mass. His peers mocked his efforts. Eventually it was his brother, a pharmacist like his father, who analyzed the white film. He found it was harmless: nothing more than crystallized fat. Lindt carried on experimenting. More cocoa beans? Or even cocoa butter? No one had tried this before! He worked on the recipe, thought it over, and played around with ingredients. But no matter what he did, he was still no closer to his goal. “Gourmet chocolate”? Nothing of the sort! The only thing he could be sure of was ridicule from his rivals. Then came that momentous Friday evening. In the flush of youth, Rodolphe Lindt left his factory with a few things he had forgotten to do – most importantly, turn off the mixing machine. Did he forget because he was in a hurry? Or was it intentional? Was he following a hunch, or perhaps trying to do something differently? We have no way of knowing. In any case, the machine kept running – over the entire weekend.

When Rodolphe Lindt entered the factory on Monday morning, he was initially very concerned about his oversight. But what he found in the mixing vat was not hard, burnt chocolate mass: it had a wonderful sheen and smell. When he came to sample it, he was the first person ever to experience chocolate melting on the tongue. He was in seventh heaven. In 187, Rodolphe Lindt set new standards with the first “melt-in-the-mouth” chocolate. Everyone wanted to buy it and try it – but that didn’t bother him, he continued to enjoy life and only went into the factory when he felt like it. The entire world wanted to learn Lindt’s secret, but no one managed to do so – fortunately.

In the meantime, Lindt’s factory was only fit to be demolished, and modernization was essential. The worry lines on Rodolphe Lindt’s forehead grew bigger. Eventually, almost 20 years after inventing “chocolat fondant” there was a meeting in Olten (halfway between Bern and Zurich) between Rodolphe Lindt and Rudolf Sprüngli, who had also built a strong reputation for his own chocolate and entrepreneurial spirit. Lindt suggested that Sprüngli should buy the Lindt brand and the secret of the conching process. This meeting in Olten marked the start of Lindt & Sprüngli’s long success story.

What actually happens in the conche?

Conching is a key factor in determining the quality of the chocolate. Conching is the final stage in the chocolate manufacturing process when it is possible to influence the texture, melting properties, and taste characteristics of the end product.

Show moreHere too, the aim is to create the best possible taste and aroma profile. Although the previous grinding stage in the rolling mills ensures the particles are evenly distributed in the chocolate, these tiny particles can still form clumps. Intense shear forces in the mixer, or conche, help to break down these clumps again. At the same time, the chocolate mass heats up, allowing the unwanted volatiles and bitter acids to escape.

This releases the fat bound in the pores and significantly improves the flow properties of the chocolate. In addition, most of the water is removed, allowing the correct moisture balance to be achieved. This is important for producing a good melting texture. Last but not least, the dough-like mixture, which assumes a powdery texture after being passed over the rough and fine rollers, is converted into a liquid chocolate mass in the conche, with liquid components such as cocoa butter also being added to the mix. After conching, the chocolate mass is ready to be made into chocolate tablets, hollow figures, and pralinés.

-

Best ingredients

Only the finest ingredients from the world’s best terroirs are good enough for Lindt’s Master Chocolatiers

only the best ingredients are good enough

Top quality is the most important criterion in the meticulous selection of our raw materials. This not only applies to the main ingredient, cocoa beans, but to all other materials such as hazelnuts, almonds, and vanilla. We source these ingredients from the world’s best growing regions and monitor their quality in our own laboratory when the goods enter our factory.

Finest creations deliver a unique tasting experience

The manufacture of premium chocolate requires the very best ingredients. Lindt Master Chocolatiers therefore take enormous care when choosing raw materials, and leave nothing to chance. Lindt & Sprüngli sources its premium cocoa beans from the world’s most exclusive regions of origin, such as Ghana, Latin America (mainly Ecuador), the Caribbean, Madagascar, and Papua New Guinea. What’s more, all the other ingredients such as sugar, and dried milk powder, hazelnuts, almonds, and vanilla are subject to rigorous standards regarding their origin and quality standards. For example, the milk powder we use in our milk chocolate products is even made by our suppliers according to our individual specifications.

Show moreWhen raw materials arrive in our production facilities, they are once again checked by our in-house laboratory to make sure they meet our high quality standards. In the case of cocoa beans and hazelnuts, for example, a sample product is sliced open with a guillotine. The image of this cross-section allows our experts to assess whether the quality meets our high standards. Additional quality checks are performed over the course of the entire production process. Special care is also taken when continuing to process the raw materials. For example, hazelnuts and almonds are freshly roasted and then pass straight on to the next stage of the production process. This ensures the chocolate retains the special roast aroma that gives a fresh, crisp taste experience.

Our global marketing departments are involved in intensive research into chocolate trends and consumer tastes as the company continues to develop new, innovative flavors. Once a range of potential new products has been selected, it’s the turn of the Lindt Master Chocolatiers. Working together with leading suppliers, we then determine the best raw materials for the new chocolate varieties. This is a laborious process that can take months or even years. Only the very best ingredients are good enough for our premium chocolate products.

-

PRODUCT PERFECTION

The Lindt Master Chocolatiers decorate their creations with attention to detail and wrap their masterpieces in elegant packaging.

attention to detail

Lindt Master Chocolatiers are consummate professionals who are only satisfied once their products are perfect. The final touch is the meticulous decoration of the end product and the packaging. Here, for example, freshly the exquisite perle de cocoa are placed on pralinés by hand, the gold foil around the Gold Bunny is polished to a high sheen, and an elegant bow is added to the gift packaging. Lindt Master Chocolatiers are only satisfied when everything is perfect, and the product can be transferred to the shop shelf.

refined with passion

Lindt Master Chocolatiers are masters of their craft and are fully aware that the presentation and visual appeal of their chocolate creations are just as important as the tasting experience itself. The elegant appearance of the products is no accident. Lindt Master Chocolatiers can draw on a vast pool of expertise and have developed a keen eye for detail over many years, passing on their know-how through perfectly made chocolate masterpieces.

Show moreOne of the important steps in finishing the product is coating the fine Lindt pralinés with chocolate. This requires the chocolate to be perfectly tempered to ensure it retains an attractive sheen as it cools down and has a crisp, firm texture when the consumer bites into it. This is followed by the stylish decoration of the products where nothing is left to chance – one of the reasons why Lindt & Sprüngli is the world’s leading producer of premium chocolate.

Pralinés are decorated by hand with freshly roasted almonds or chocolate balls and given exotic names such as Amande de Luxe and Perle de Cacao. The gold foil around the Gold Bunny is polished to a high sheen and the characteristic red collar placed around the neck by hand. To finish things off, the products are put in elegantly designed packaging which also protects them from external effects and preserves their exquisite aroma.

Finally, the products arrive in retail outlets and in Lindt’s own shops, where once again great emphasis is placed on a neat, visually appealing presentation.